Remove the filter from the cassette within one hour of completion of sampling and place it in a PTFE-lined screw capped vial to be shipped to the labouratory. The NIOSH 7600 sampling method stipulates filter removal from the cassette. The background levels found on the treated filters raises the detection limit and we do not recommend them for sampling.įinal collection techniques and extraction procedures between the two methods differ greatly. In studies, we have found the background levels of hexavalent chromium on these treated filters to be five times greater than our detection level.

When sampling chrome plating operations the OSHA ID 215 allows the use of a 37-mm polystyrene cassette containing NaOH coated binderless quartz fibre filters. When sampling in conditions that are dusty, switch out the sample cassettes to limit filter loading.

Dusty conditions may warrant multiple samples to avoid filter overloading. Precaution should be taken to not exceed 1 mg total dust loading on the filter. A 25-mm PVC filter can be used with the OSHA method for placement within a welding face shield. While NIOSH Method 7600 states a flow rate of 1-4 liters per minute (LPM), OSHA Method ID-215 states 2 LPM as a recommended sampling rate.īoth methods involve collection on a 5.0 um pore size, 37-mm diametre polyvinyl chloride (PVC) filter in a polystyrene cassette filter holder. Both methods use similar collection media with slight variations in the sampling rates, different total sample volume and shipping preparation techniques. SGS Galson currently offers analysis for hexavalent chromium by NIOSH Method 7600 and OSHA Method ID 215. According to ACGIH, the agent is carcinogenic to humans based on the weight of evidence from epidemiological studies. Both soluble and insoluble forms carry the notation as a confirmed human carcinogen. The American Conference of Governmental Industrial Hygienists (ACGIH) has adopted a time-weighted average of 50 ug/m 3 for water soluble compounds and 10 ug/m 3 for insoluble hexavalent compounds.

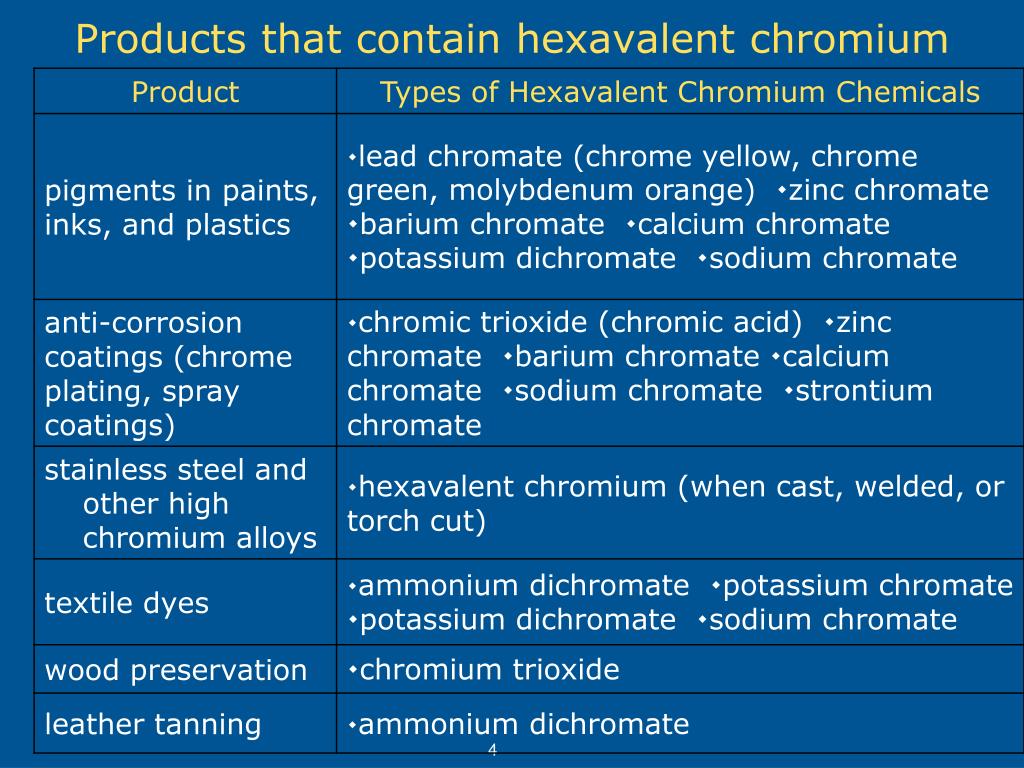

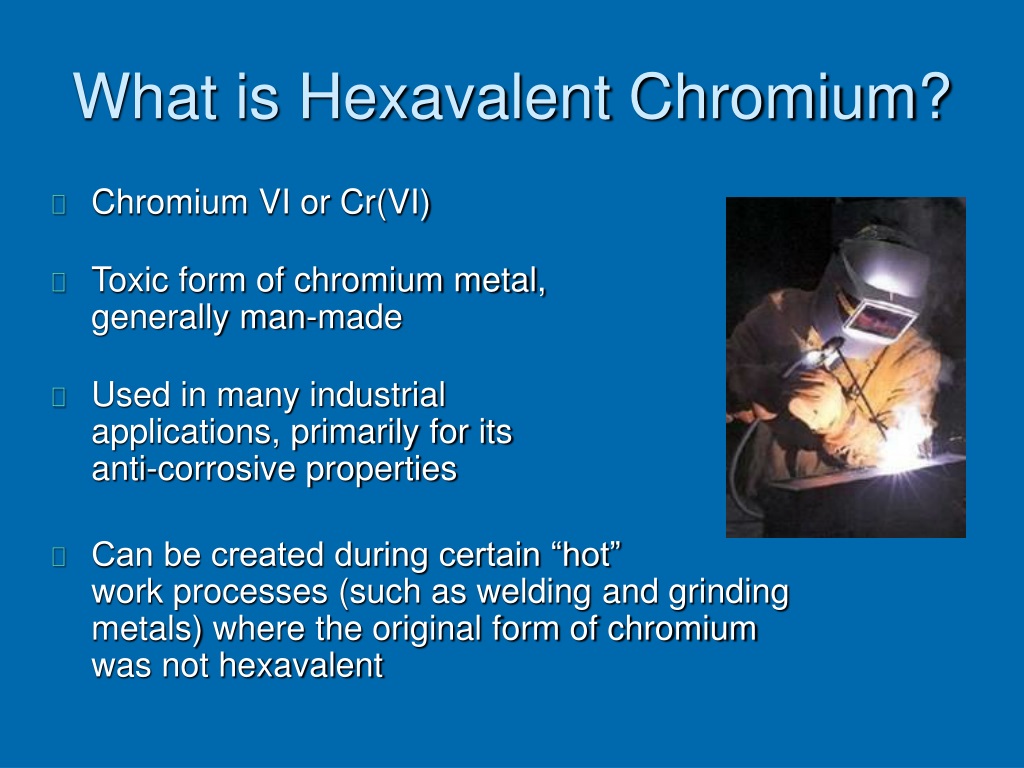

NIOSH considers all hexavalent compounds (including chromic acid, tert-butyl chromate, zinc chromate, and chromyl chloride) to be potential occupational carcinogens. The National Institute of Occupational Safety and Health (NIOSH) currently recommends an exposure limit of 1 ug/m 3 for a 10-hour TWA for all hexavalent chromium compounds. The OSHA final standard also addresses ancillary provisions for employee protection with preferred methods for controlling exposure, respiratory protection, protective clothing and equipment, hygiene areas and practices, medical surveillance, hazard communication, and recordkeeping. The document reduces the permissible exposure limit (PEL) ceiling to an 8-hour time-weighted average (TWA) of 5 ug/m 3, with an Action Level (AL) of 2.5 ug/m 3 for hexavalent chromium compounds. In the Federal Register on February 28, 2006, the Occupational Safety and Health Administration (OSHA) published a final standard for occupational exposure to hexavalent chromium. The Environmental Protection Agency (EPA) and the International Agency for Research on Cancer (IARC) concurs that there is sufficient evidence implicating hexavalent chromium in air as a human carcinogen. The Department of Health and Human Services (DHHS) determined that because some hexavalent chromium compounds have been associated with lung cancer in workers, and caused cancer in animals, certain compounds such as calcium chromate, chromium trioxide, lead chromate, strontium chromate and zinc chromate are known human carcinogens. Other processes that use hexavalent chrome products are corrosion inhibitors, drilling mud operations and even toner for printers.īreathing hexavalent chromium levels greater than 2 micrograms per cubic metre (ug/m 3) for extended periods of time can cause runny nose, sneezing, itching, nosebleeds, ulcers and holes in the nasal septum. Sources for hexavalent chromium include electroplating operations, battery makers, textiles, chemical manufacturing, wood preserving and stainless steel welding activities. Of particular interest are chromium trivalent and hexavalent states. Chromium is a naturally occurring element found in rocks, soil, plants and animals, and present in the environment in several different forms. Depending on the operating process, monitoring hexavalent chromium (Cr(VI)) for workplace exposures can be a daunting task. Soluble or insoluble: that may be a question of the past. HEXAVALENT CHROMIUM UPDATED OSHA ID 215 FOR HEXAVALENT CHROMIUM (VERSION 2) 9/2006 Hexavalent Chromium

0 kommentar(er)

0 kommentar(er)